3D Printing Phoenix is used in various ways. Manufacturers produce spare parts and jigs and incorporate them into end-use products like cars and appliances.

The first step in 3D printing is creating a virtual design of the object using CAD software. The model is then sliced into hundreds or thousands of thin layers.

Prototypes play a crucial role in the product development process, from concept modeling to engineering and testing. 3D printing is a powerful tool that can significantly speed up prototyping, saving businesses time and money.

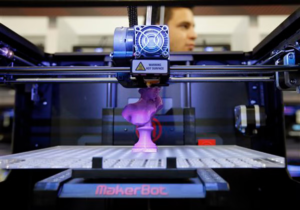

3D printing is an additive manufacturing technique that builds up a physical prototype layer by layer. The printed prototype is constructed using a digital design file from various materials, including plastic or metal. This allows engineers to test different design iterations without the need for lengthy and costly production runs.

The first step in product design is creating a concept model or proof-of-concept (POC). This allows designers to discuss and test ideas with stakeholders, while also evaluating a prototype’s viability. Physical concept models are more effective in driving discussion and decision making than 2D drawings or verbal descriptions. In addition, they can help with visual marketing and sales presentations, allowing companies to showcase their designs to potential investors and partners.

Once a prototype has been developed, it is subjected to rigorous testing and iteration. This feedback is used to refine the design and improve its functionality, performance, and user experience. 3D printing provides a powerful tool for rapid prototyping, reducing time and costs while ensuring that the final design is optimized for production.

Another use for prototypes is to manufacture tools, jigs and fixtures, which can be difficult or impossible to create with traditional manufacturing processes. Using a CAD design, 3D printers can quickly produce these components, removing the need for complicated or expensive tooling. This enables professionals to get to work right away and avoid costly delays while waiting for custom-made tools to be delivered.

Once the prototype has been tested and revised, it can be put into production. 3D printing allows for a high degree of customization, enabling teams to develop a truly tailored product that is fit for purpose. This is particularly important for medical devices, which must be safe, durable, and aesthetically pleasing. With 3D printing, medical manufacturers can deliver a finished product that meets these requirements.

Stratasys’s advanced printing solutions enable the creation of functional prototypes with exceptional thermal stability and high-temperature performance, preventing them from warping or deforming in harsh environments or under heavy mechanical loads. Additionally, a wide selection of materials offers versatility in the fabrication of functional prototypes, allowing developers to match the exact look and feel of their intended end products.

Custom Parts

3D printing is ideal for creating custom end-use parts and components. Rather than having to wait for quotes, businesses can upload their designs and receive pricing instantly. On-demand manufacturing also helps accelerate time to market, enabling businesses to test out new products or features before they hit the shelves.

In addition to speed, on-demand manufacturing helps reduce costs and waste. It allows businesses to produce the quantity they need, when they need it, without the expensive upfront cost of production tooling. It also helps reduce storage and inventory costs. Lastly, on-demand manufacturing is a flexible option, allowing businesses to print a single part or a hundred.

3D printing can be used for a wide range of materials including plastics, metals, wax, concrete, and ceramics. This flexibility opens up a world of possibilities that were not possible using traditional methods. For example, metals can be printed in complex geometries that would be impossible to manufacture using conventional machining techniques. Additionally, 3D printing is capable of producing parts with high accuracy and tolerances. This can be achieved through the use of layering techniques and varying the size of each layer.

While initially used for prototyping, 3D printing has evolved into a cost-efficient method for production of end-use parts and components. It is a great alternative to other industrial processes like CNC machining and injection molding. It can even help create cheaper molds for injection molding, reducing the cost of mass-producing plastic parts.

Using advanced technologies, it is now possible to manufacture end-use parts with the same precision as conventional CNC milling and injection molding. This allows businesses to scale up their production while reducing the cost of each unit and making them more competitive in the marketplace. Furthermore, 3D printing can help speed up the manufacturing process by eliminating the need for tooling and cutting down on lead times. This can also be used to make specialized parts for specific industries like medical and automotive. For example, GE Aviation’s LEAP engine uses cobalt-chrome 3D printed fuel nozzles that are 25 percent lighter and five times stronger than traditionally manufactured nozzles.

Reduced Manufacturing Costs

When companies use 3D printing to make prototypes of their products, they can reduce the cost of product development. This is because instead of having to pay for custom moulds, which can be expensive, they only need to print the digital model that will form the basis of the prototype. Similarly, the ability to print multiple variations of a part means that each design iteration can be made more quickly, with the cost incurred by constructing and destroying moulds being saved.

Another advantage of using 3D printing is that the technology allows for a greater range of materials to be used than traditional manufacturing methods. While polymer plastics are the most common print material, there is also scope for producing parts from metals and composites like carbon fiber, Kevlar and fiberglass strands, with each offering unique properties that can be matched to particular applications.

The way that raw materials are consumed in 3D printing is also more efficient than traditional manufacturing processes, as only the exact amount of needed material is added layer by layer. This eliminates waste and makes the technology resource-efficient, particularly when it comes to high-value materials. Furthermore, the printing process is able to produce complex and intricate components that would be very difficult to make with traditional manufacturing technologies. This can cut labour costs and prevent the need to stock spare parts that will not be sold, which in turn reduces storage and warehouse space requirements.

With 3D printing, it is possible to produce a single part or small series of parts in a fraction of the time that would be required with traditional manufacturing methods. This reduced turnaround times allow companies to more accurately estimate their production costs and can help them to confidently set delivery estimates for customers. Additionally, with the digital inventory management that is available with many 3D printers (particularly those with the capability to upload and store CAD data), the need for extra or spare parts can be minimized, reducing storage and warehousing costs.

In addition, the fact that a wide variety of 3D printing technologies exist, including Fused Deposition Modelling (FDM), SLS powder technology and MJF (Multi-Jet Fusion) means that there is a huge selection of options in terms of price and complexity. Typically, the more complex or intricate a design is, the higher the price will be, though there are exceptions.

Environmentally Friendly

As businesses look for eco-friendly options, 3D printing is gaining traction as a viable way to produce prototypes. The technology utilizes a lot less energy than traditional manufacturing methods, so it’s environmentally friendly on that front.

3D printing also eliminates waste that’s often produced with traditional manufacturing methods, resulting in lower material costs and more efficient production. In addition, companies can recycle filaments and reuse them for future projects. This reduces the demand for virgin plastic, which has been linked to climate change.

Traditional petroleum-based plastics are not biodegradable, creating long-lasting environmental pollution. These contaminants, including microplastics, have been found in marine ecosystems and can even enter the food chain. With 3D printing, companies can use biodegradable materials that degrade naturally and create a positive impact on the environment.

In addition, 3D printing reduces the need for shipping and air cargo, reducing the amount of fuel needed. Traditionally, the same product must be shipped from the factory to the packaging company and then to the store, which requires a significant amount of fuel and exhaust emissions. In the future, the manufacturing and distribution of products could be performed locally, lowering carbon footprints and allowing companies to focus on customization and quality.

The growing popularity of 3D printers is helping to foster a new generation of innovators who prioritize sustainability. This trend may lead to a future where innovation walks hand-in-hand with preservation, guiding us towards a sustainable future.

While there are still challenges in the manufacturing of a truly green process, 3D printing is advancing rapidly and will continue to revolutionize how we live. Its advantages are enormous, and it is poised to transform every aspect of human existence.

From manufacturing cars to building homes, 3D printing is already changing the world around us. The technology is not only transforming our physical world, but it’s also being used to build models and help with scientific research and medical applications. Some scientists are even exploring the possibility of using the technology to construct extraterrestrial habitats. In the near future, we can expect to see more innovations in the construction industry as well as in other industries that will be transformed by 3D printing.